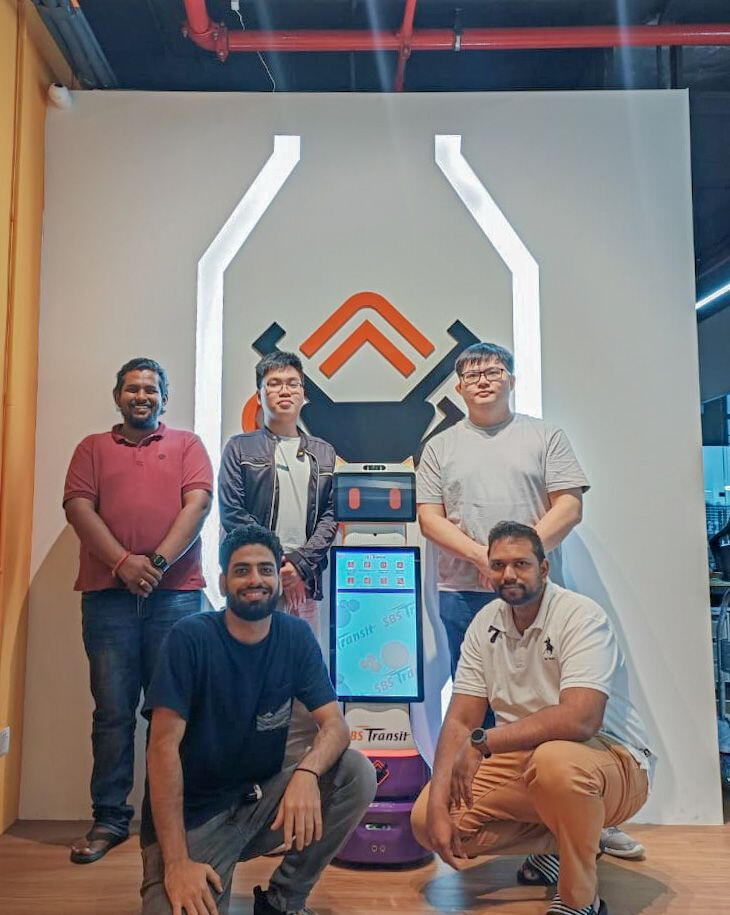

Robyn V1 & V2

Concierge Cobot — September '24

• My Role

Lead Engineer — CAD Design & Optimization, DFM & DFA Layout, Rapid Prototyping, Electrical Design, Control and Power PCB, Sensors, Actuators, Depth map calibration

Team

Sathish Kumar, PM

Mohammed Gamal, LE

Benedict Choong, ME

Sathiaswaran Muthu, SW

Aqeel, WD

Sean Lee, UI/UX

• Timeline & Status

14 months, Launched in September 2024

• Overview

Based on our market study we saw a lack of user engagement in hospitals, museums, malls, and train stations when providing assistance, so we wanted to introduce a robot that automates the kiosk experience, helping users find information and navigate their surroundings more efficiently.Led the end-to-end R&D, CAD design, and QA cycles, leveraging 3D printing for rapid prototyping and fabrication. Integrated motion control systems, sensors, actuators, and custom electrical architectures with optimized PCBs.The primary focus of this project was to design a friendly, companion-like identity for the robot, allowing it to seamlessly integrate into crowded public spaces. It works alongside service operators, adapting, interacting, and responding as a trusted extension of its environment.

• PROBLEM SPACE

Creating the "Identity"

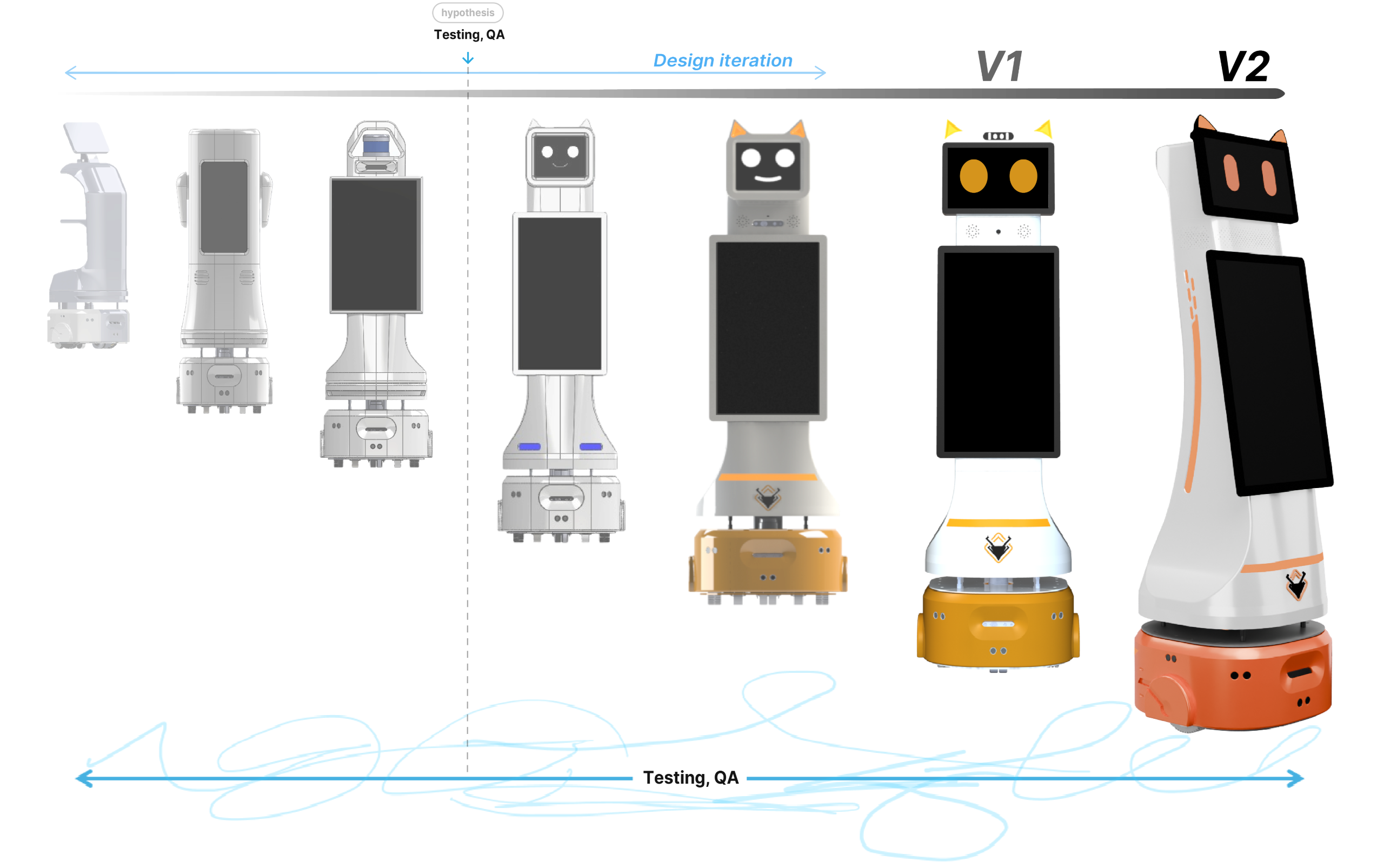

• The design iteration was both challenging and time-consuming, focusing on creating a companion-like identity.• Early iterations focused on functional and utilitarian forms, gradually transitioning to a more approachable, character-inspired design, to foster a friendly connection with users.• Intensive testing ensured precise form optimization while balancing structural integrity, and aesthetics Figure 1.1.

Building Hardware like software. Not only CAD models. Not only concepts. 6 real, physical prototypes—designed, built, and tested.

1.1 Design Iteration IMAGE

THE CHALLENGE

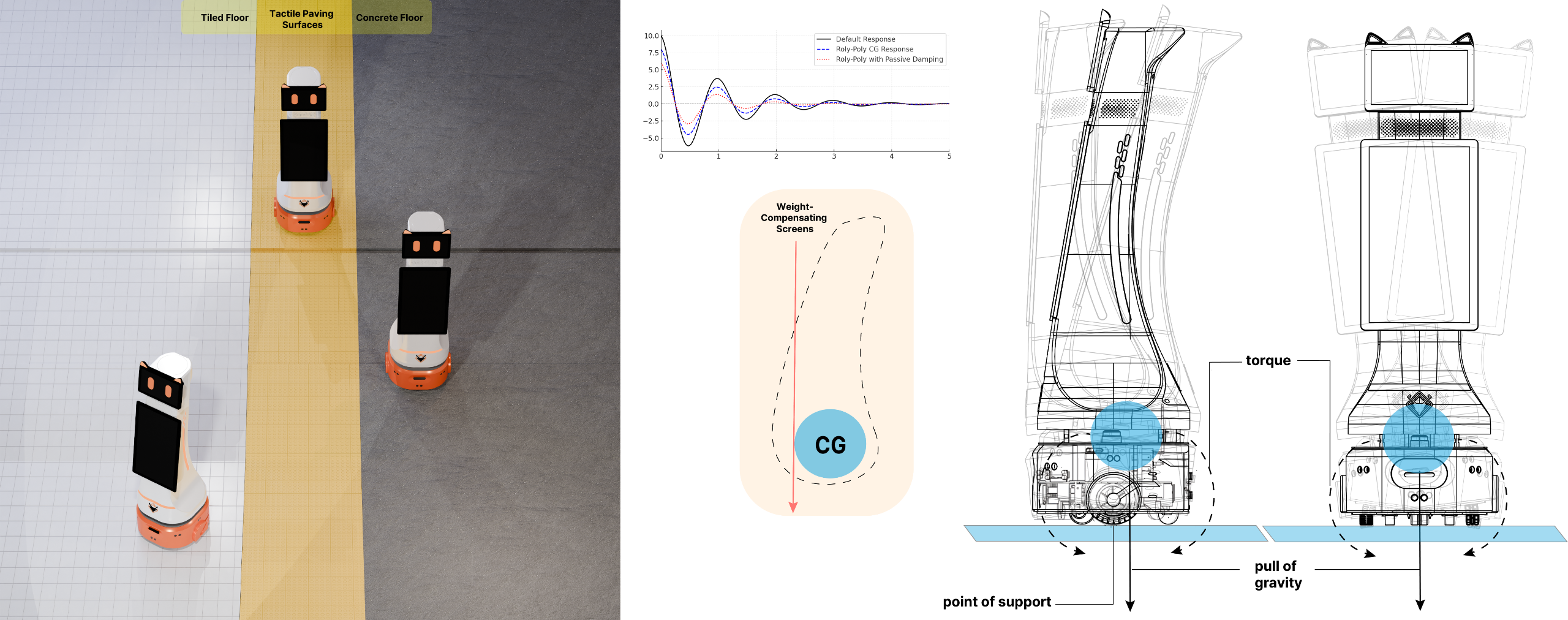

Base AMR was originally designed for smooth environments, but we needed a solution to handle dynamic public settings.

Instead of overhauling the entire AMR design, we adopted a “roly-poly” approach — placing heavier components at the bottom and shaping the chassis with a gentle arc Figure 1.2.

• Strategy

Starting from what we already had.

By strategically placing the main control components and power systems in the lower chassis and leveraging the passive suspension as a damping factor, we amplified this effect. This design not only overcame a critical industry-wide mobility challenge but also contributed to our successful tender.The distinctive curved profile, combined with a carefully mounted 21" screen angled for user interaction, leveraged the physics of mass distribution to deliver a safe, approachable, and consistently balanced structure.

1.2 Roly-Poly Approach IMAGE

Clearing the fog — for all the ways we playtest.

Showcases for extreme disturbances subjected to barebone structure In-house

1.3 Tilt Testing INTERACTIVE

IRL performance

Showcases for casual navigation through station tactile surfaces on-field

1.3 Vibration Response Testing INTERACTIVE

• factors

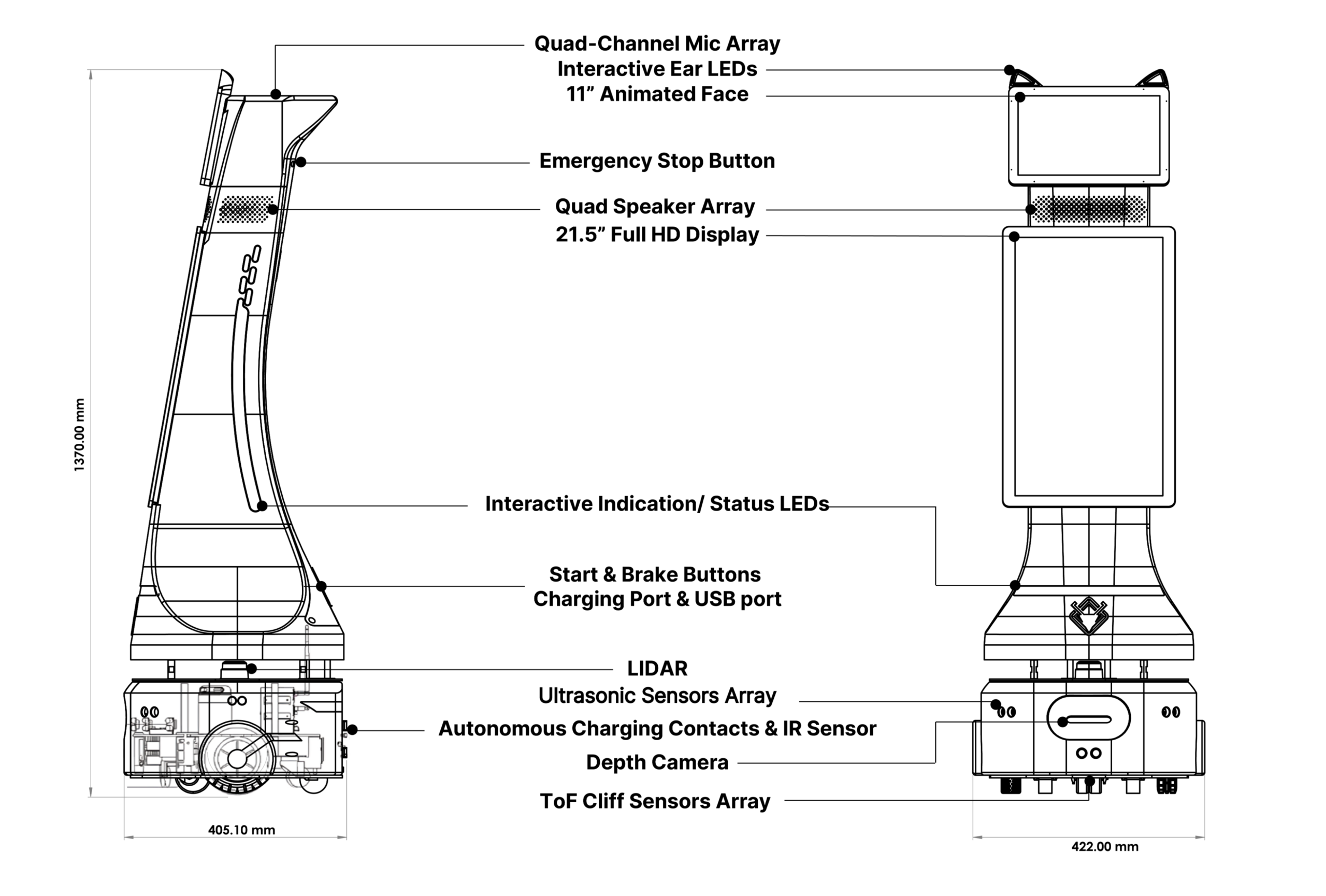

Sensing, audio & visual interactions.

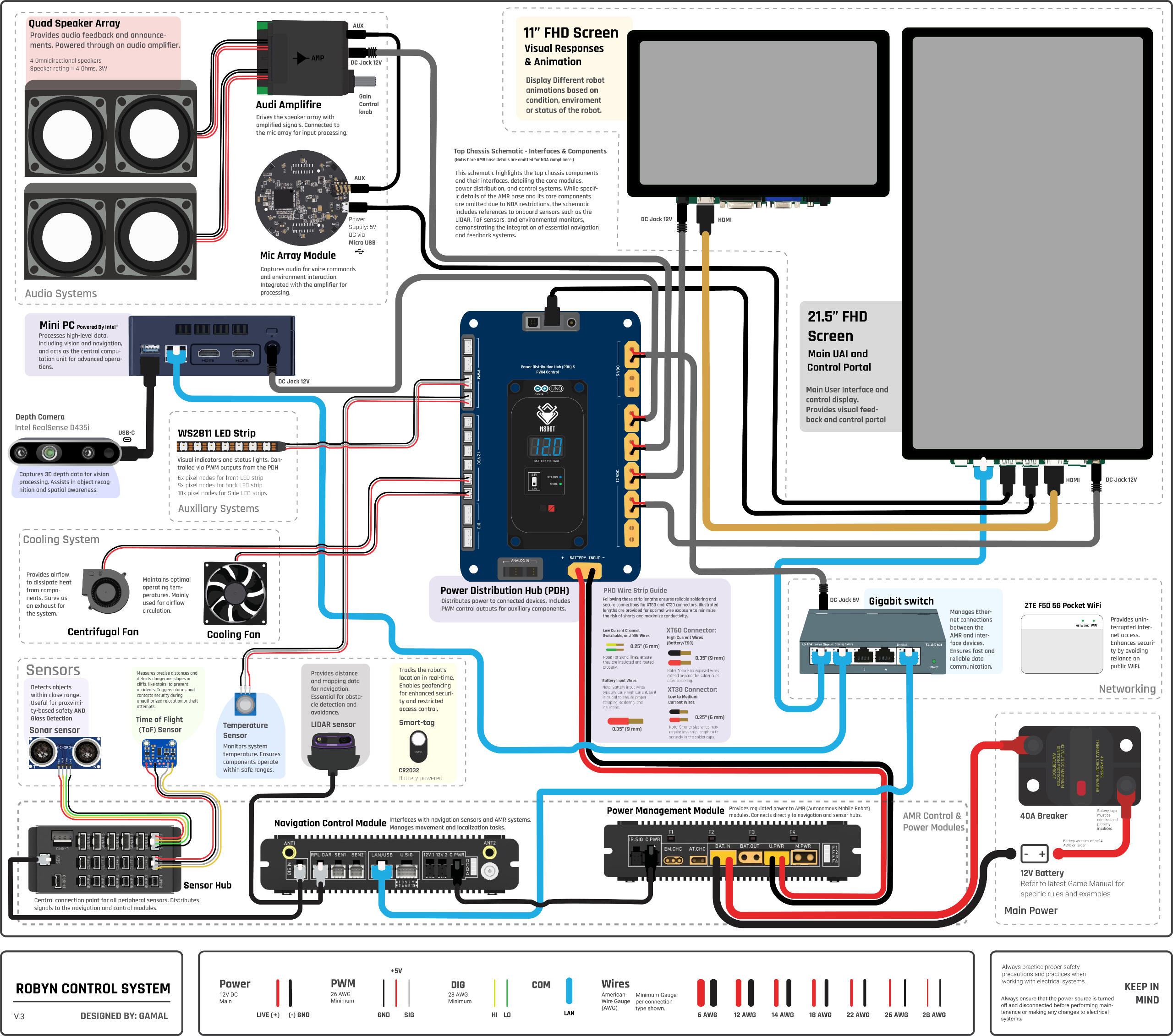

Audio Interaction

A compact quad-speaker array housed in a custom-designed speaker box with vibration-damping diaphragms delivers crisp sound, even in crowded spaces. Paired with a quad-microphone array featuring advanced acoustic echo cancellation and noise suppression, this setup ensures clear two-way communication and effective announcements.Environment Sensing

Tricky lighting and high-traffic conditions were addressed with modular calibrations for depth cameras, sonar, and ToF sensors. These adjustments optimize range and sensitivity, ensuring safe and precise navigation by dynamically controlling speed.Visual Interaction

Interactive status lights and an animated expressive face provide instant visual cues, creating an intuitive and welcoming interface. These visual elements complement the device’s design, enhancing user engagement while reinforcing confidence in its capabilities.

1.4 Hardware Breakdown IMAGE

• Sustainability

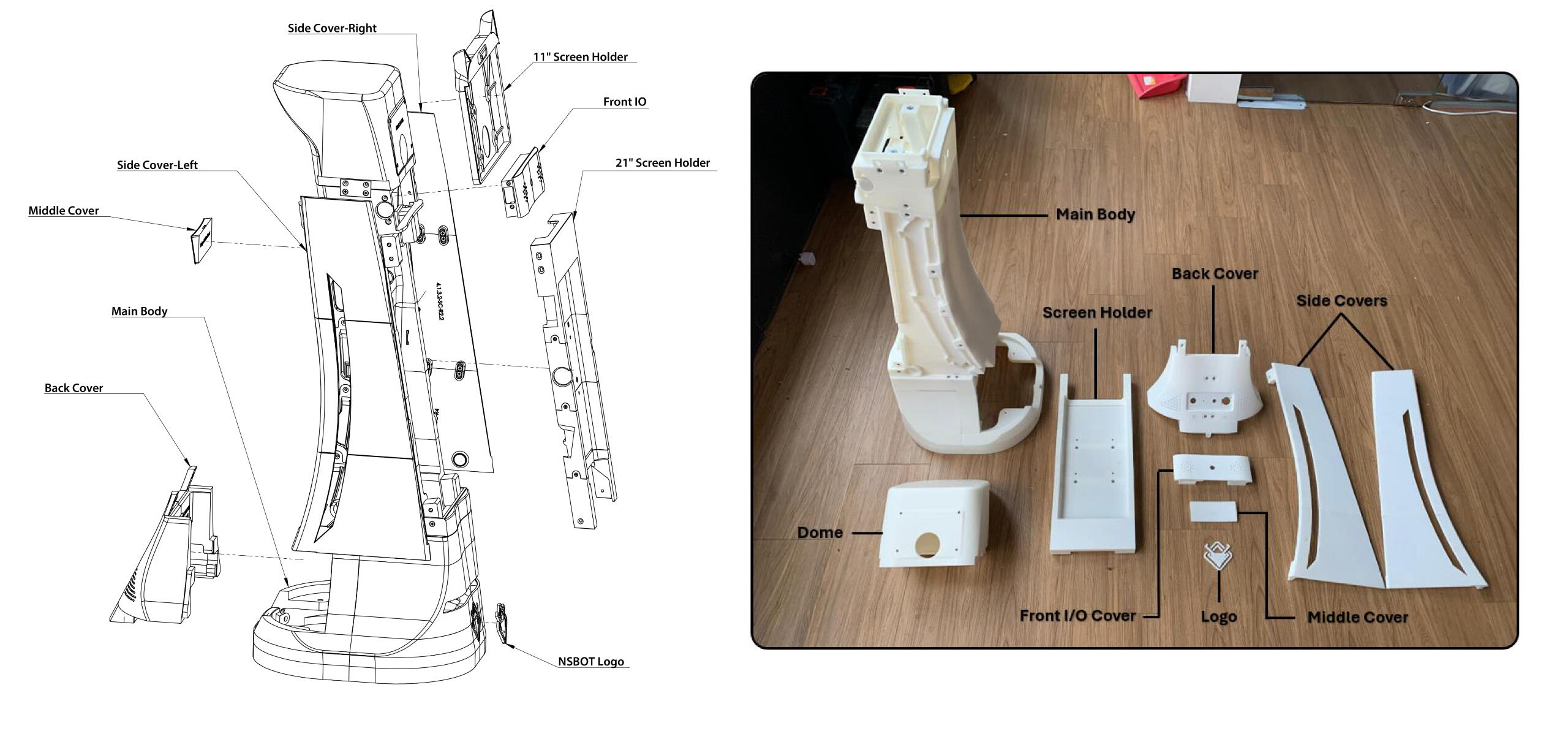

Hyper Customizable.

Fully 3D-printed body reinforced with an aluminum endoskeleton for added strength & durability.Our in-house production unlocked a modular design with high customizability.Industrial-grade post-processing bridged the gap, fortifying heat resistance while delivering a sleek, polished finish.Robyn's design was intended to support internal and external hardware integration access points to meet location-specific needs, including options like PTZ camera for security, 3D LiDAR sensor for advanced navigation, different internal processing units, I/O devices etc.

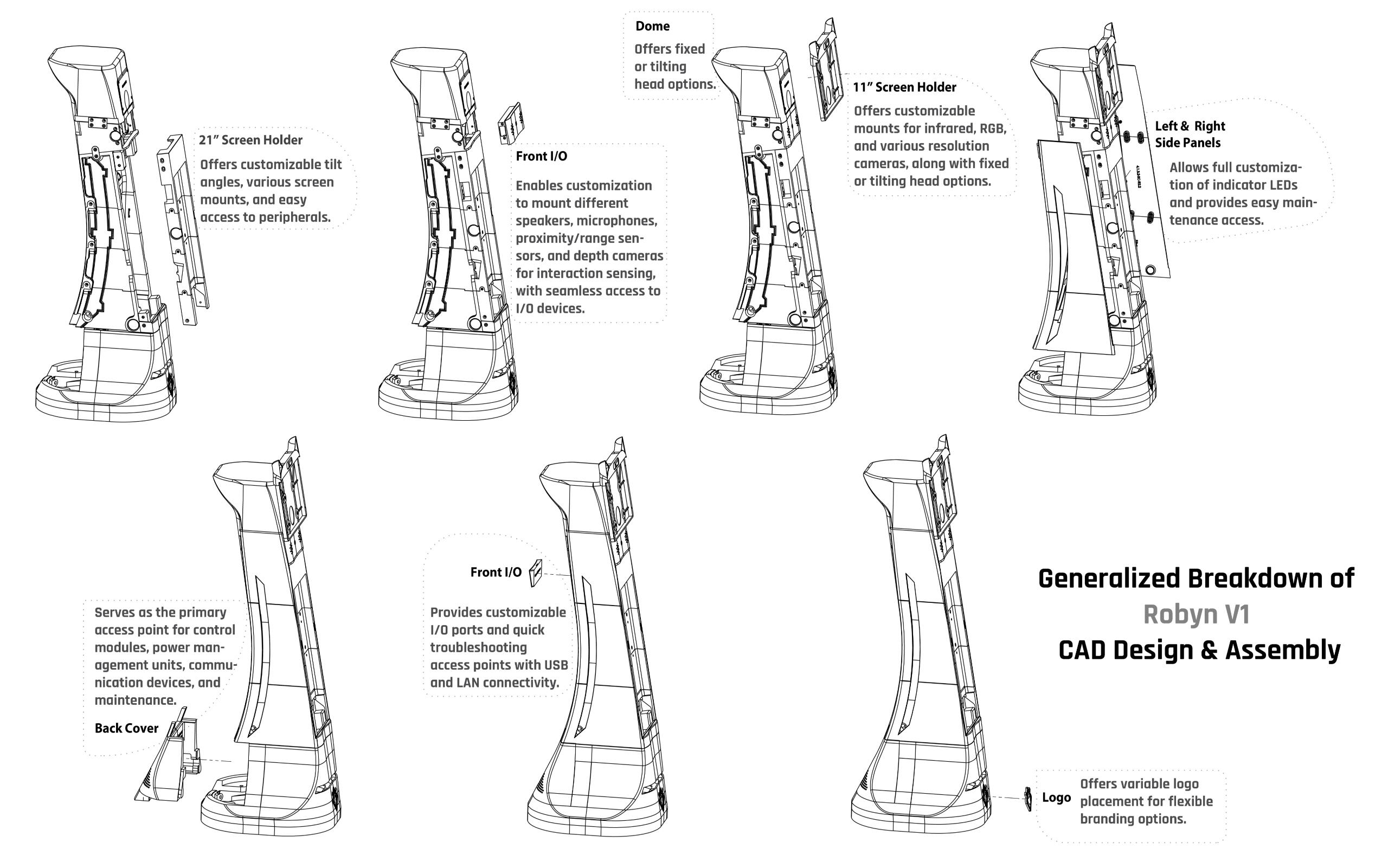

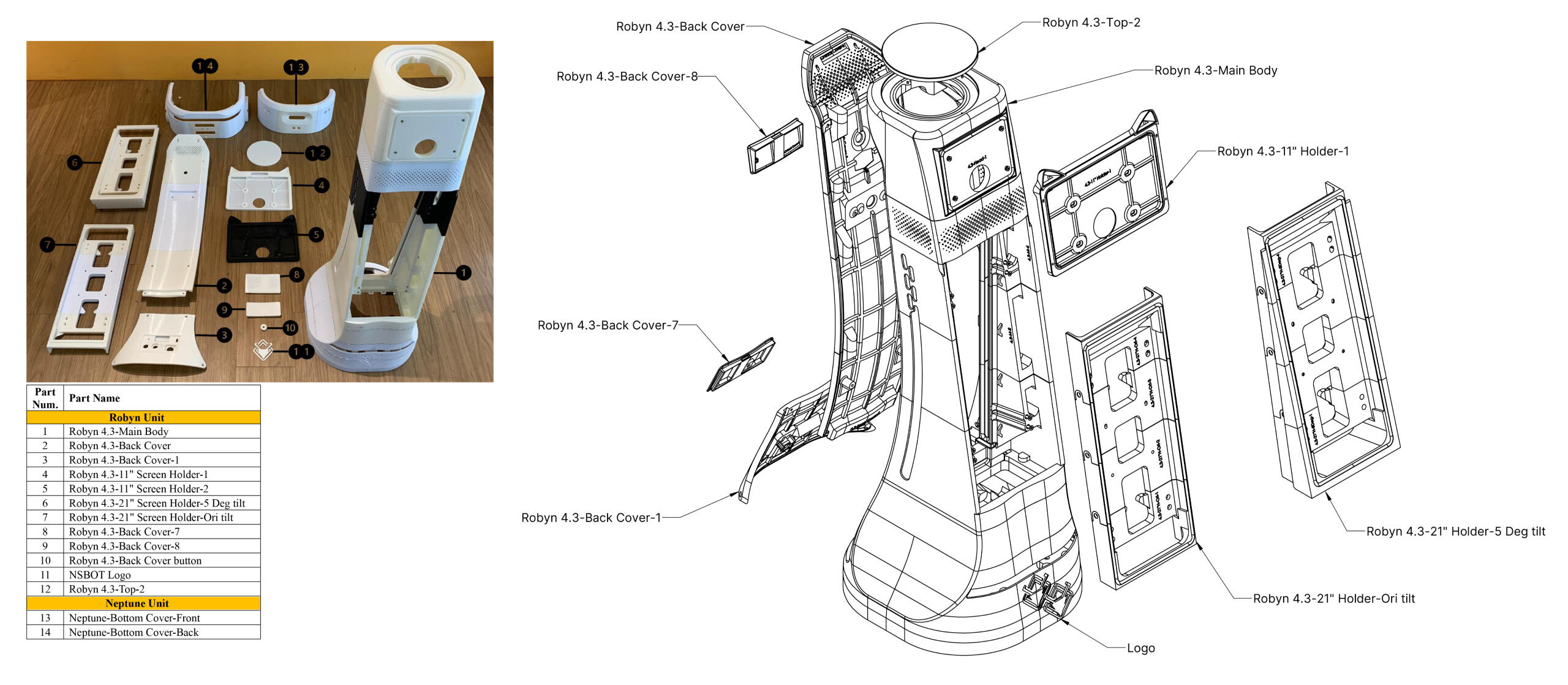

Robyn V1.

The design incorporates an outer swappable shell, enabling seamless modularity across various components as shown in Figure 1.5.

Pro: Easily tailored solution

Con: Limited ability to achieve a high IP rating for semi-outdoor environments.

1.5 Robyn V1 3D CAD & Printed Body Breakdown IMAGE

CAD HIGHLIGHTS AT A GLANCE

V1 Main assembly and customization approach

1.6 Robyn V1 3D CAD & Assembly Breakdown IMAGE

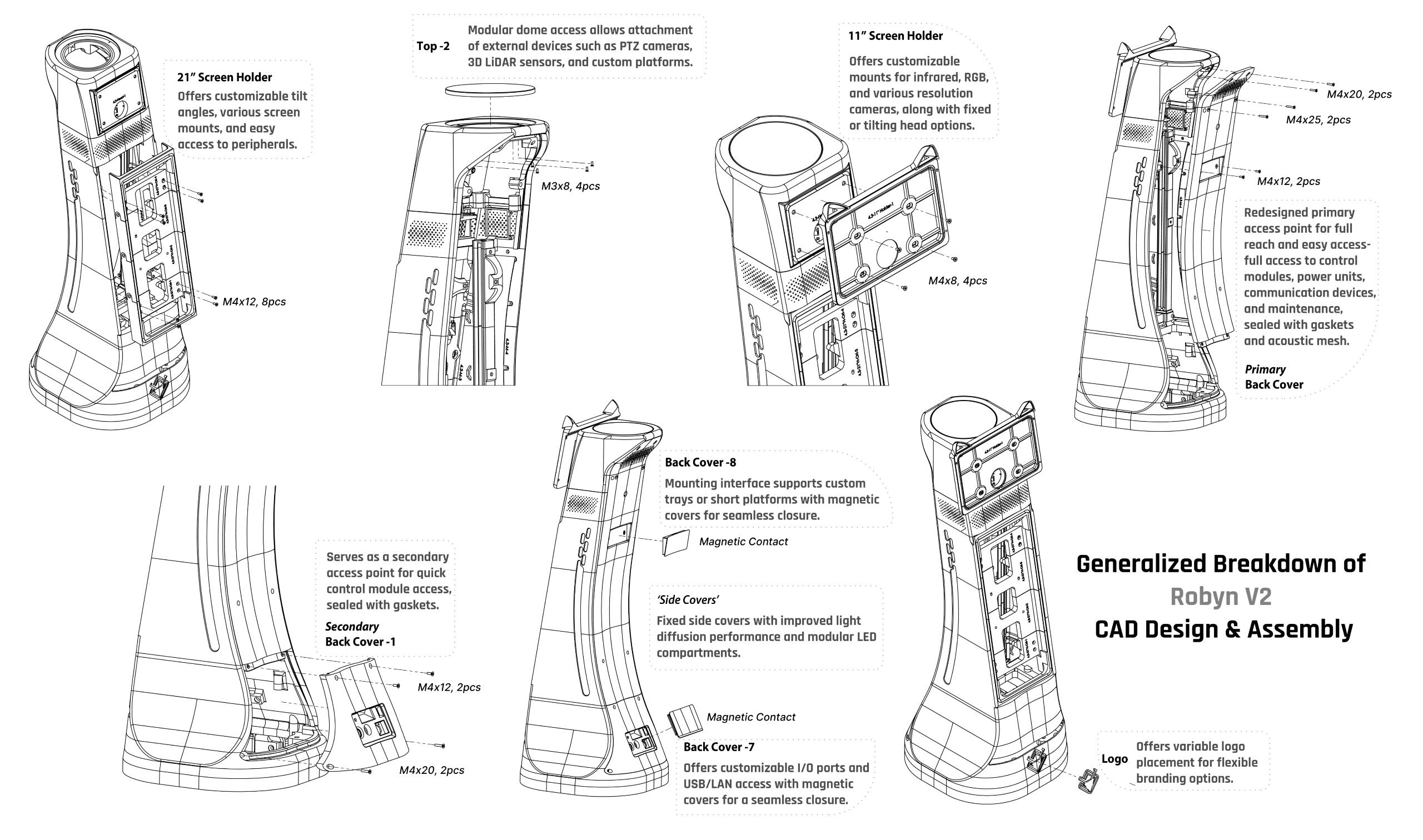

Robyn V2.

The design approach pivoted towards:• Designing an IP54-rated structure through gasket closures on all modular parts and covers with precise tolerances, sealed exposed points, adding I/O covers, and acoustic mesh for venting.

• A modular dome for attaching external devices.

• A customizable mounting interface on the back cover, accommodating custom trays or short platforms.

• Fully adjustable internal compartments that can be added or removed, providing flexible mounting options for internal devices along a dual aluminium extrusion endoskeleton as shown in Figure 1.7.

Pro: Higher IP rating for targetting semi-outdoor environment deployment. Lighter weight structure with lower center of gravity.

Con: Limited overall customized parts.

1.7 Robyn V1 3D CAD & Printed Body Breakdown IMAGE

CAD HIGHLIGHTS AT A GLANCE

V2 Main assembly and customization approach

1.8 Robyn V1 3D CAD & Assembly Breakdown IMAGE

1.9 Electrical Control System Breakdown IMAGE

• The Final Experience

Deployment Highlights

Showcases for some active deploements of Robyn.

• Reflection

Moving forward.

As we look ahead,

our vision extends into broader public engagement.

• We plan to explore enhanced AI-driven interactions.• In parallel, we will continue to prioritize sustainable manufacturing practices.• From an operational standpoint, a dedicated focus will be placed on remote diagnostics and predictive maintenance. This will allow for real-time health monitoring of some sub-systems. Currently, we're 30% done with this implementation.

Developing Robyn required a delicate balance of engineering ingenuity and user-centric design. Our biggest hurdle was crafting a friendly, approachable presence in busy public areas—an effort that underscored the importance of form, materials, and mass distribution for both aesthetics and stability.Iterative prototyping proved invaluable; each physical build offered actionable data, guiding our transition from purely functional structures to emotionally resonant, companion-like forms.Equally vital was the cross-disciplinary collaboration between teams.A key insight was viewing the robot not merely as a product but as an extensible platform, open to future innovation. This perspective informed our modular approach to hardware and software integration, enabling quick adaptations to evolving needs and environments.

• Next Project

CYERA — Secure Delivery Cobot

Portfolio updates coming soon in 2026.